Our Approach

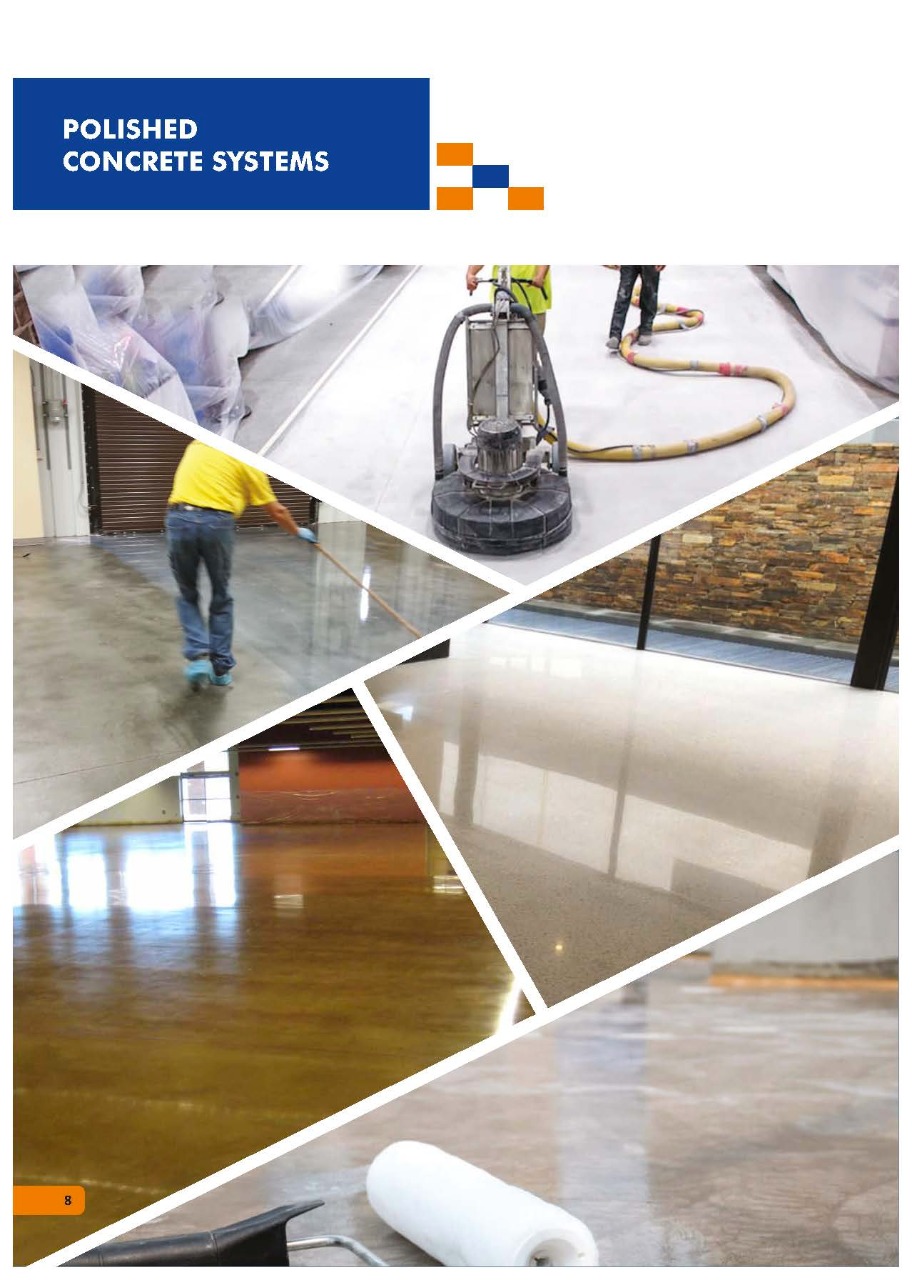

GRIND AND SEAL POLISHED CONCRETE PROCESS

This system is the standard polished concrete system where the concrete surface is ground

to the desired level using appropriate abrasives. Grouting and patching may be required to fill

any voids, holes, cracks or imperfections followed by densification process using necessary

lithium silicate or potassium silicate densifiers. The surface is then cleaned and prepared

for the application of either a gloss or matte surface coating, or an impregnating enhancing

sealer.

Extending the life of existing concrete floors is possible – and it can be done with little

interruption to any facility. As an experienced specialist, we IBCS can assess the floor and put

together an action plan and restore existing concrete.

Low Maintenance Solutions

Polished concrete floors are low maintenance, as they are more durable and easier to clean than

many flooring options

Polished Concrete Systems

Sustainable, low maintenance, durable and Easier to clean

WHY POLISHED CONCRETE SYSTEMS

Polished concrete is considered a good sustainable floor option because it makes use of the

materials already present. Most modern buildings are built on a concrete slab; polishing the

exposed concrete eliminates the energy and material consumed by applying a floor covering.

It is something to consider when building or modernizing towards a greener solution.

Polished concrete floors are low maintenance, as they are more durable and easier to clean than

many flooring options. Its relatively high coefficient of friction can make it non-slippery.

Polished concrete reduces dust mite and allergen.